A general summary of project progress as of March 12th, 2022. This week was our demonstration to our professors, which happened on Wednesday, March 9th. The plan was to visually showcase the completed system, movement of the printhead and possibly a print demo if time allowed.

Software

Slicer

An open source slicer named Slicer4RTN is used to generate the GCode. It is built on top of multiple slicers like Slic3r and CuraEngine and additional logics to generate GCodes for 3D printers with Rotating Tilted Nozzle(RTN), which is a 4-axis printer. It has the functionality of slicing parts at the angles requested. Below are gif showing several sliced parts at a 45° angle.

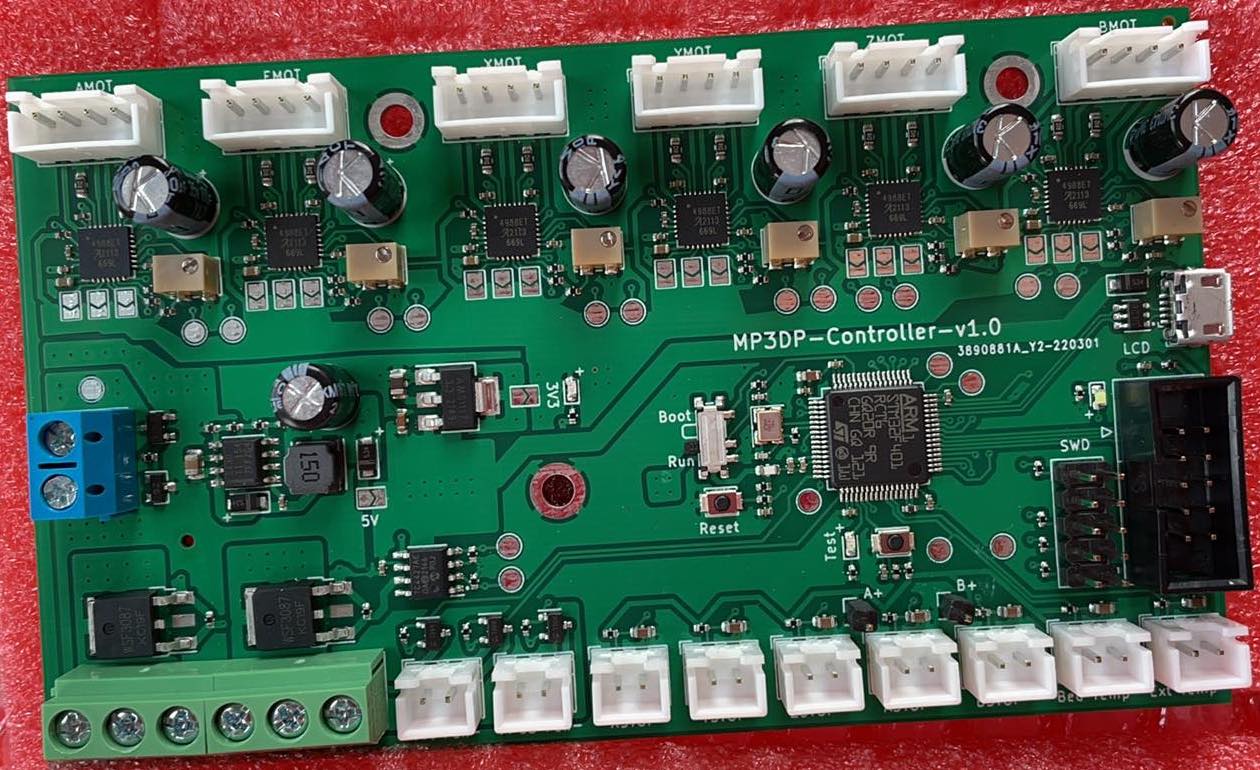

Electrical

The PCBs did not arrive in time for the demo itself, but they arrived a few days later. From there, some preliminary testing would begin. From the first inspection, there did not seem to be any issues with the boards. The power rails for 24V, 5V and 3.3V were all functional, though the 5V rail was instead at 4.6V. However, since there aren’t many 5V components on the board, especially with digital logic, this discrepancy is not an issue. The motor controllers were also configured with a reference voltage set at 0.96V to limit the stepper motor current to 1.2A.

System Functionality at the Demo

The general functionality of the system was working by the demo date, though we did not have time to configure for a more complex print beside a standard test overhang print.

The gif below shows the first successful supportless 90 degree print from our 3D printer, something that would not be possible with a standard 3D printer.

Additionally, the below gif shows the movement demonstration that was shown on the day of the demo. It consists of each of the Tilt and Turn axes moving on their own as well as together.